E-commerce order volumes surged by 28% year-over-year in 2023, exposing bottlenecks in fulfillment infrastructure. Major players like Amazon now operate 120+ fulfillment centers globally to prevent stockouts. DHL's 2022 deployment of autonomous forklifts in Belgium reduced order processing errors by 34%, demonstrating how automation mitigates scaling risks.

Real-time inventory tracking cuts average delivery times by 1.8 days by synchronizing stock levels. Urban micro-fulfillment centers now operating within 10 miles of 65% of EU metro areas enable 2-hour delivery windows. Retailers using cloud-based WMS achieve 92% inventory accuracy versus 73% in manual operations, reducing overselling.

Leading 3PL providers handle 41% of omnichannel fulfillment through AI-powered networks. Robotic palletizing systems process 1,200+ items/hourâ€"3à faster than manual laborâ€"while IoT sensors maintain optimal storage conditions. This operational edge lets brands offer same-day shipping at 19% lower costs than in-house fulfillment.

Centralized inventory visibility prevents overselling by updating stock levels across all channels within seconds. API-driven integrations between WMS and e-commerce platforms achieve 99.6% accuracy, reducing stockouts by 34%. A 2023 supply chain automation study found real-time sync boosts customer satisfaction scores by 22%.

Advanced WMS automate 73% of routine tasks through:

These workflows reduce manual errors by 89% and cut processing time from 45 to 9 minutes per order.

A logistics provider achieved 98.7% on-time delivery by integrating WMS with robotics and predictive analytics. The system:

This model reduced fulfillment cycle times by 63% while maintaining 99.4% inventory accuracy.

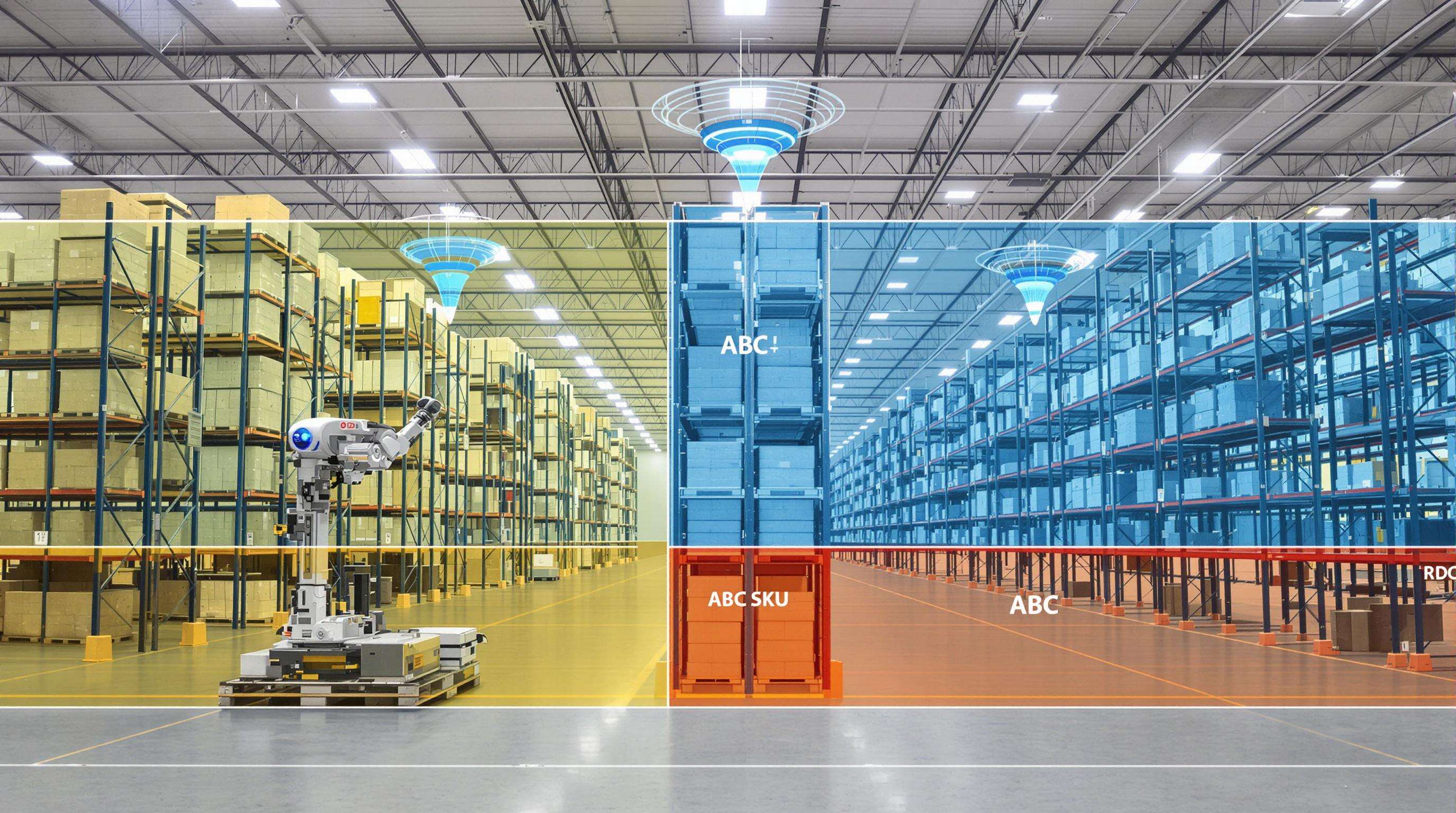

Warehouses categorize SKUs into:

This reduces picking errors by 18% and accelerates order processing by 27%.

AI achieves 94.6% demand prediction accuracy, a 22% improvement since 2020. Models analyze sales velocity, geopolitical factors, and social trends.

Cross-docking cuts storage durations by 42%:

| Metric | Traditional | Cross-Docking |

|---|---|---|

| Dock-to-Stock Time | 5.2h | 1.1h |

| Storage Costs/Unit | $3.18 | $0.89 |

| Order Lead Time | 72h | 19h |

Automated sorting handles 92% of cross-docked parcels.

AI balances inventory across channels in real time, reducing holding costs by 18-22% while maintaining 99.5% order accuracy.

Modular packaging systems meet platform rules like Amazon's Frustration-Free standards, eliminating 92% of compliance delays.

Smart routing directs returns to the nearest hub, cutting processing costs by $1.20-$1.80 per unit and shortening refund cycles to 72 hours.

Cobots accelerate order processing by 60%, with 30-45% labor cost reductions within 18 months.

Pharmaceutical distributors using IoT-controlled zones reduced spoilage by 83%, critical for vaccine storage.

Blockchain with WMS cut documentation errors by 91% in food shipments, enabling 40% faster customs clearance.

Warehousing services provide the necessary infrastructure to store, manage, and distribute goods efficiently, ensuring smooth order fulfillment and delivery in e-commerce operations.

Real-time inventory tracking keeps stock levels synchronized across sales channels, minimizing overselling and allowing for quicker response times in dispatching orders.

Third-party logistics providers offer specialized services such as AI-powered networks and robotic systems, which enhance operational efficiency and reduce costs for businesses handling large volumes of e-commerce orders.

Warehousing services integrate with order processing systems via advanced software and API-driven solutions, allowing for seamless synchronization of inventory with sales channels and automation of routine tasks to improve accuracy and speed.

Innovations include the use of ABC analysis for SKU prioritization, AI-driven demand forecasting, and cross-docking strategies, all aimed at improving operational efficiency and reducing costs.

Hot News

Hot News2024-11-15

2024-11-11

2024-11-06

2024-10-31

2024-10-28

2024-10-25